Making the world a better place

We take pride in the service we deliver – fast efficient and cost effective.

We have a huge amount of experience with UKCA Marking in accordance with BS EN 1090 and can assist you fully with the entire process, from start to final certification.

We are all about helping you achieve your best individually and as a company. Our invigilators are time-served welders so fully understand the process and want you to pass NOT fail!

All the work that we perform is in accordance with National, European and Internationally Recognised Standards, including:

The primary purpose of welding procedure qualification is to demonstrate that the joining process proposed for construction is capable of producing joints having the required mechanical properties for the intended application.

When qualifying welders, the emphasis is placed on the welder’s ability manually to manipulate the electrode, welding torch or welding blowpipe, thereby producing a weld of acceptable quality.

Here are some of the procedures we cover MIG/MAG, MMA, TIG and FLUXCORE in Mild Steel, Stainless and Aluminium and can certify to BS EN 15614, ASME, BS EN 9606, BS EN 287-1, BS EN 4872 and many more!

Magnetic Particle Inspection (MPI)

Magnetic Particle Inspection (MPI) is a non-destructive testing method that can detect surface and subsurface flaws in ferromagnetic materials. Ideally used on welds and other areas cracking may be present but not visual to the naked eye.This is mainly on carbon steel, however stainless steels and other non-ferromagnetic materials would be better suited to dye penetrant inspection.

This method is also useful for testing on-site as it is portable.

Dye Penetrant Inspection (DPI)

Dye Penetrant Inspection is used for detecting surface breaking defects such as cracking in both ferrous as well as non-ferrous materials. However for ferrous materials Magnetic Particle Inspection is recommended due to its sub surface ability. This non-destructive testing technique and is a cost-effective method used to locate surface breaking flaws such as cracks, porosity, laps, seams and other surface discontinuities.

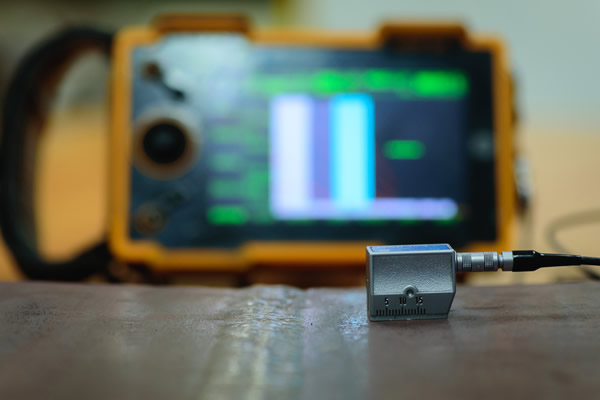

Ultrasonic Inspection

Ultrasonic Inspection is used to predominately measure the thickness of materials. Ultrasonics are used during most inspections and can be applied to almost every asset.

Ultrasonics used on the following:

Storage Tanks / Stack tower & columns / Pipelines / Pressure Vessels / Boiler Tubes

There exists a large number of tests, many of which are standardised, to determine the various mechanical properties of materials. In general, such tests set out to obtain geometry-independent properties; i.e. those intrinsic to the bulk material. In practice this is not always feasible, since even in tensile tests, certain properties can be influenced by specimen size and/or geometry. Heres what we can offer

We provide a 2 day Responsible Welding Coordinator (RWC) course in accordance with the requirements of EN 1090-1, with a 3rd day onsite Gap Analysis and Initial Type Testing (ITT) , which is a requirement, helping you comply with the mandatory regulation of CE marking for structural steel.

The role of the RWC is to control and supervise all welding activities, and ensure the steel structures meet the adequate levels of mechanical resistance, stability, serviceability and durability.

The two-day RWC training course covers the duties and requirements of a RWC for execution classes 1 and 2. This course is accredited by a number of nominated third party accreditation bodies including: BM Trada; ISOQAR; Centre For Assessment; LRQA (Lloyd’s Register Quality Assurance); BBA (British Board of Agrément); BSI (British Standards Institute).

Course topics include:

The RWC training is delivered by our tutor, who is qualified EWS/IWS (European Welding Specialist/International Welding Specialist) and PCN Level 3 in Visual Inspection. It is also possible to carry out the course at your premises if you require to put 2 or more delegates through the course.

Please call us on 0333 014 7720. Or email us on info@isocertonline.net for a fixed price quotation, visit or video meeting.

Here at ISO-Cert Online Ltd we will take all the stress away from you so you can concentrate on running your business. We offer a complete package, so no need to worry about anything!

It’s cost effective and also you have the confidence to know you will achieve UKCA marking with minimum stress.

Associate of UKAS accredited Notified Body